Key Takeaways:

- Modern pipeline mapping and maintenance rely on advanced technologies such as GIS, GPR, smart pigs, and drone surveillance.

- Routine inspections, proactive cleaning, and data-driven predictive maintenance are essential for prolonging pipeline life.

- Ensuring regulatory compliance and mitigating corrosion are critical elements of a holistic maintenance strategy.

- Integrated approaches using pipeline integrity tools streamline both mapping and maintenance processes.

Pipeline structural health is crucial for reliable energy resource movement. Modern mapping and maintenance techniques are evolving to incorporate advanced solutions for precision, faster intervention, and risk management. Leveraging advanced pipeline integrity tools is an industry standard for maintaining safe, productive networks and aligning with regulatory requirements.

Initial Pipeline Mapping

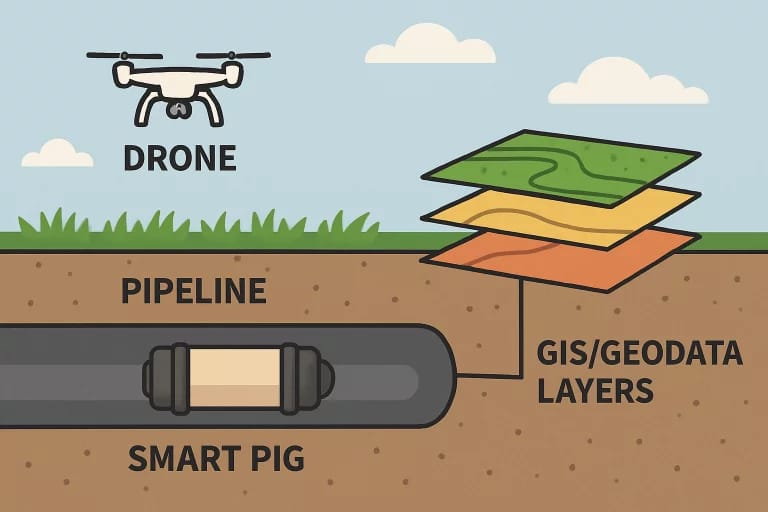

Pipeline projects start with meticulous mapping of the route and environment. Geographic Information Systems (GIS) and Ground Penetrating Radar (GPR) create digital representations of the pipeline corridor, allowing planners to identify sensitive regions, optimize routes, and predict challenges. When paired with pipeline integrity tools, this combination reduces the risk of costly surprises and safety incidents in the field, enabling safer construction, streamlined permitting processes, and robust maintenance strategies. Investment in these mapping tools is crucial for successful pipeline projects.

Implementing Advanced Inspection Techniques

Pipeline integrity management relies on routine and advanced inspections to detect issues before they become hazardous or expensive. In-Line Inspection (ILI) tools, such as smart pigs, gather detailed information about wall thickness, corrosion, cracks, and subtle deformations. These insights help operators anticipate problems, plan preventative maintenance, and avoid catastrophic leaks or ruptures. Drone surveillance, equipped with high-definition cameras, thermal imaging, and gas detection sensors, provides birds-eye visibility on encroachments, leaks, and security breaches. These technologies help operators spot defects quickly and accurately, ensuring consistent pipeline integrity and reducing response times to anomalies or emergencies. These technologies are crucial for maintaining operational efficiency and upholding public and environmental safety standards.

Routine Cleaning and Maintenance

Pipeline systems’ performance and safety depend on regular cleaning and maintenance. Over time, deposits like scale, wax, or sediment accumulate, limiting flow rates and increasing corrosion risk. Traditional pigging tools are essential for debris removal, but hydrojet cleaning offers an eco-friendly alternative. Regular cleaning operations preserve peak flow efficiency and allow for close-up condition assessments. Implementing a disciplined schedule can prevent outages, reduce maintenance costs, and extend the lifespan of valuable infrastructure.

Corrosion Monitoring and Prevention

Corrosion is a significant threat to aging and newly installed pipelines due to exposure to moisture, chemicals, and changing temperatures. Cathodic protection systems effectively neutralize corrosive processes, but modern pipelines are also coated in anti-corrosive layers to shield the metal from moisture and salts. Continuous monitoring via embedded sensors ensures protective measures are working effectively. Combining these proactive techniques with routine manual inspections minimizes corrosion threats, safeguards public safety, and optimizes pipeline operational lifespan.

Data Management and Predictive Maintenance

Pipeline systems have digital sensors, smart inspection devices, and surveillance systems, producing a constant operational data stream. Advanced data management platforms are crucial for capturing and organizing this information. Predictive maintenance powered by machine learning and artificial intelligence helps operators identify subtle patterns and early-warning signals. This data-driven approach reduces reactive maintenance, extends shutdown intervals, and ensures reliable, economic operation of vital infrastructure, transforming pipeline maintenance into a competitive advantage.

Compliance with Regulatory Standards

Pipeline operators must navigate complex regulatory obligations to ensure safety and environmental protection. To avoid penalties, companies conduct internal audits, maintain documentation, and educate staff on emerging standards. Proactive compliance management uncovers operational improvement opportunities. Integrating compliance into daily workflows using automated systems and checklist tools minimizes oversight and fosters a safety-oriented corporate culture. Staying current with evolving regulations ensures legal operation and builds trust among regulators, stakeholders, and the community.

Conclusion

The future of pipeline mapping and maintenance is being defined by seamless technology integration, advanced predictive analytics, and an unwavering commitment to the highest standards of compliance and safety. By embracing modern tools and a data-informed approach, operators ensure their infrastructure remains robust, environmentally responsible, and economically sound in the face of rising demand and stricter oversight. Staying proactive and informed through advanced pipeline integrity tools, regular education, and industry partnerships will empower operators and stakeholders to navigate the complexities of modern energy transportation and thrive as the industry continues to advance.

Must Read: Pipeline Cleaning Solutions for Modern Infrastructure